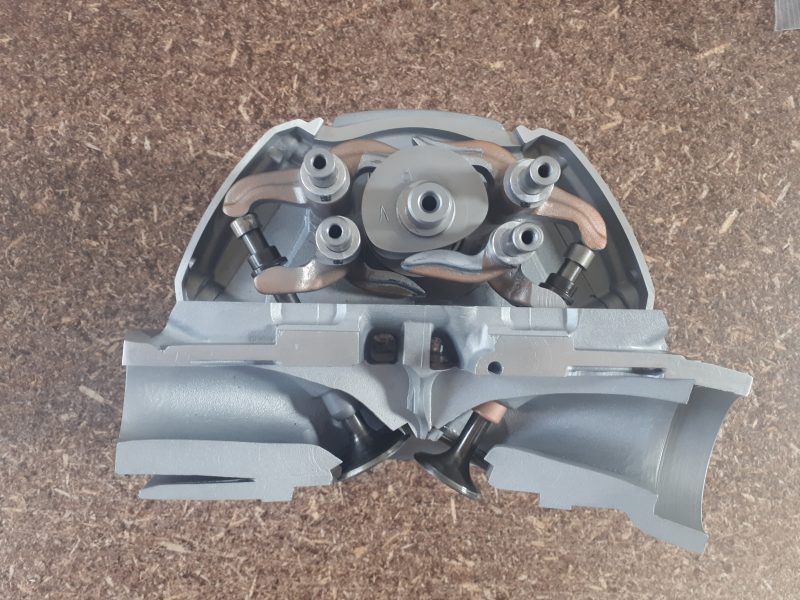

As a Christmas gift, and to add an exhibit to the Zweiradmuseum (Two wheel Museum) in Neckarsulm, Belt and Bevel cross sectioned a Ducati Desmo cylinder head to add to the museum’s collection. Below is a video, photo and the accompanying description. Museum link is here https://www.zweirad-museum.de/ and is worth the visit!

Desmodromic.

Coming from two Greek words “Desmos” meaning linked or bonded and “Dromos” for course, track, guide it is used to describe a controlled guide, in this case the control of the intake and exhaust valves in a 4 stroke engine. In this example you will see four cam lobes and 4 rockers, two of the cam lobes are common shape with an opening ramp and the rocker that follows this lobe opening the valve. In a regular 4 stroke engine a valve spring holds the valve against the rocker; loading the camshaft, and then closing the valve as the cam ramp rotates away from the open position. You will note the example here also has a second set of cam lobes that run a set of closing rockers, pulling up on the valve to positively close the valve (Desmodromic).

Why use the Desmodromic system? When relying on a spring to shut the valve, there can be variation between the profile of the cam face and the valve closing due to the time it takes for the valve spring to return to its original state. This is most noticeable at high RPM where the time from closed to open to closed is very short. Using the Desmodromic system, there is no delay to return to its original state as the valve is being pulled (Controlled) back shut. This allows within reason and materials almost infinite valve speed and ramp lift shape. This point of lift shape is also very important in the Desmodromic system, in that with a conventional valve spring setup the ramp profile needs to be forgiving on the spring to not sharply open or close the valve as to let the spring keep up with the profile. In the Desmodromic system the cam ramp can be much more aggressive, with faster opening and closing profiles without the worry of the valve not keeping up. The opening and closing speed can also then be translated into performance as the fuel mixture and gasses are more precisely moved.

The downside to Desmodromic systems in the modern time is that there is the mass of the rocker to contend with in high RPM situations this is magnified meaning that rocker to cam face galling is the limiting factor with the modern Desmodromic system. Modern overhead cam with the cam lobe acting directly on a valve lifter and multi coil valve springs have surpass the issues that the Desmodromic was originally engineered for. Furthermore, the Desmodromic system is complex compared to the modern competitors, needing fine manufacturing tolerances, maintenance tolerances and tighter manual service intervals.

Notable History of Desmodromic valve control:

1896 Gustav Mees – Mentioned in patents

1910 Austin marine engine, 300 bhp “Irene I”

1914 Grand Prix car, Delage and Nagant used Desmodromic

1933 Azzariti Italian manufacturer uses Desmodromic in 173cc and 348cc two cylinder engines

1954 Mercedes-Benz 300SLR and W196 use Desmodromic valve control

1956 Ducati, under Ing. Fabio Taglioni begin use of Desmodromic in Grand Prix race bike.

1959 Maserati Brothers use Desmodromic in their last O.S.C.A race car.

1968 Ducati begin using Desmodromic in their production motorcycles, beginning with Single cylinger Mk3

This particular example cross sectioned cylinder head is from a 1995 Ducati 400 Supersport.

60° included valve angle, belt drive camshaft, air/ oil cooled.